Wild clay in my practice

Using wild clay offers a deeper connection with the material and the land that it comes from.

The wild clay in my area is unlike perfectly formulated clay bodies or commercial clays, and working with it means allowing the material to shape the work and deferring to its limitations.

It also means less reliance on long-distance supply chains and large-scale mining operations for materials. Working with local clay allows me to contribute to the stewardship of the land that produces my materials.

Stewardship

There are social and environmental factors to consider when locating and harvesting clay. For example, in Unama'ki, much of the visible clay can be found along the shorelines, which are vulnerable to erosion and collapse. It’s best to locate clay layers and then travel inland to dig up clay (with permission) in order to protect the integrity of the shorelines.

Some rules I follow when harvesting are:

Aways re-cover the holes that I’ve dug from

Only take the materials that I need

Collect any garbage found along the way

Avoid digging in fragile ecosystems

Processing

After harvesting, I then need to process the clay to remove rocks, excess organic materials, or sand. This involves drying the clay, slaking it, straining it, and drying the clay again.

It then needs to be processed. This involves testing the clay for workability and plasticity, shrinkage, vitrification temperature, and water absorption. There are also aesthetic considerations like colour and texture. Most clays in my area are reddish brown in colour.

Check out some testing photos below.

-

Testing glaze materials

In the summer of 2025 I attended a natural clay workshop led by Dave McMillan. We tested a variety of found natural materials for for their glaze-making potential.

-

Wild clay bar tests

Wild clay is formed into bars and cones to determine shrinkage, absorption, and firing temperatures.

-

Clay body formulation

I am experimenting with clay body formulation for translucency and porosity. These bars use grolleg and tile 6 clays and were vitrified at Cone 6.

-

Hand building with wild clay

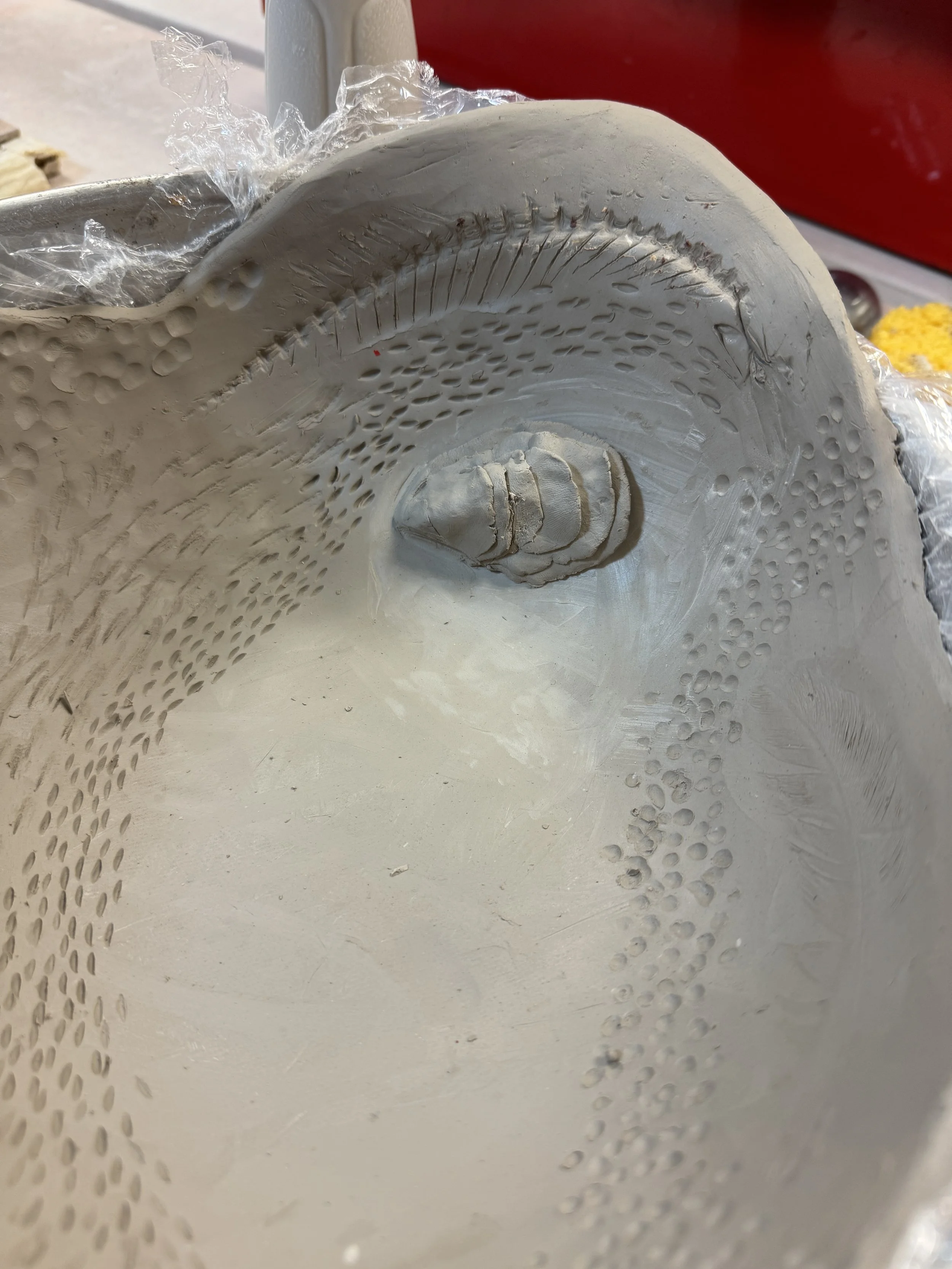

I used a combination of commercial and processed wild clay for this large bowl. It was easy to work with, though there were minor issues with bloating during firing.

-

Hand building with local clay process photo

A medium-sized hand built bowl using a combination of wild and commercial clay. The clay allowed me to make thin walls and delicate sculptural elements, but the bowl needed support while drying to prevent slumping.